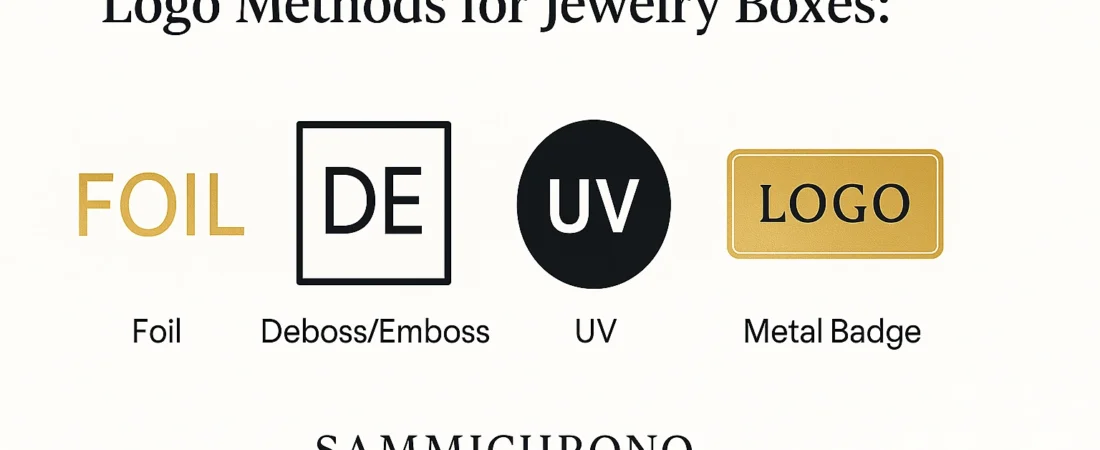

our logo is the most visible signal of quality on a jewelry box. The application method you choose changes how customers perceive your brand—luxury vs. sporty, classic vs. contemporary—as well as durability, cost, and lead time. This guide compares foil stamping, deboss/emboss, UV print, and metal badge so you can choose the best finish for your next run of custom jewelry boxes with logo.

Why Logo Application Matters

A jewelry box is both packaging and a keepsake. Unlike a disposable mailer, it stays with your customer for years. That’s why a well-executed logo finish can:

- Elevate perceived value (and justify premium pricing)

- Increase brand recall at unboxing and every reuse

- Reduce returns from scuffs, peeling, or color drift

- Keep collections visually consistent across seasons

The optimal method depends on your substrate (PU leather, paper-wrap, wood, fabric), logo complexity, order quantity, and the luxury signal you wish to send.

Foil Stamping (Hot Foil)

What it is: Heat and pressure transfer a metallic or pigmented foil onto the surface via a custom metal die.

Why brands choose it

- Immediate luxury cue: Gold/silver foil pops on PU and premium paper wraps.

- Crisp edges: Clean lines for serif marks and monograms.

- Color library: Metallics (gold, rose gold, silver), matte foils, holographic options.

Best fit materials

- PU leather, paper-wrapped board, some smooth fabrics. Works great on high end jewelry box collections that emphasize shine.

Considerations

- Requires a die; best for mid-to-large runs.

- Very fine hairlines can break; keep stroke ≥ 0.2–0.3 mm.

- Avoid heavy texture under the logo area (flattened patch improves transfer).

Cost & lead time (relative)

Durability

- High when properly transferred; resistant to light handling. Aggressive abrasion can dull metallic sheen over time.

Deboss / Emboss

What it is:

- Deboss presses the logo into the surface to create a recessed effect.

- Emboss raises the logo above the surface (usually with a counter-die).

Why brands choose it

- Tactile premium feel without shine—timeless and subtle.

- Great for minimalist brands or tone-on-tone marks.

- Can be combined with foil for a foil-deboss effect.

Best fit materials

- PU leather and paper-wraps with minimal crack risk; avoid brittle coatings. On heavy textures, details may soften.

Considerations

- Stroke weight and counters (holes in letterforms) must be tested—too thin can collapse.

- Requires precise pressure and dwell; keep logo away from edges/curves where pressure is uneven.

Cost & lead time (relative)

Durability

- Excellent—no ink or foil to scuff. Effect remains for the lifetime of the box.

UV Print (Spot UV / Digital Gloss)

What it is: Clear or colored varnish cured by UV light to create gloss and slight relief. Can be registered onto printed color or applied as a standalone glossy mark.

Why brands choose it

- Sharp micro-detail for thin strokes and small copy.

- Modern look: High-gloss highlight on matte surfaces.

- Color control: Black, white, or CMYK with UV layer.

Best fit materials

- Paper-wraps and certain coated PU panels (test adhesion first). Great for geometric logos and fine linework.

Considerations

- Not as scratch-resistant as metal; heavy friction can haze the gloss.

- Color fidelity depends on the base substrate and primer.

Cost & lead time (relative)

- $–$$ (no metal die; setup is faster) | lead time: fast

Durability

- Good for display and normal use; prolonged abrasion may reduce gloss.

Metal Badge (Emblem / Nameplate)

What it is: A custom-made metal emblem (zinc alloy, brass, stainless), finished by electroplating/paint, then mechanically fixed (rivets, screws) or bonded.

Why brands choose it

- Maximum luxury signal: weight, shine, and depth.

- 3D geometry: raised edges, cutouts, enamel fills.

- Long-term durability: won’t rub off like inks.

Best fit materials

- PU leather and rigid paper-wrap. Perfect for flagship or limited editions where the box is part of the product.

Considerations

- Highest unit cost; engineering needed for placement and backing plate.

- Adds weight and handling time on the line.

- Export compliance: ensure no sharp edges and stable attachment.

Cost & lead time (relative)

Durability

- Excellent; can outlast the substrate. Just protect during shipping to avoid dents.

Side-by-Side Comparison

| Method | Look & Feel | Detail Handling | Durability | MOQs/Tooling | Cost (relative) | Best Use Cases |

|---|---|---|---|---|---|---|

| Foil | Lux, metallic, high contrast | Medium–High | High | Metal die required | $$ | Premium PU/paper wraps, gift editions |

| Deboss/Emboss | Subtle, tactile, timeless | Medium | Very High | Metal die required | $$ | Minimalist brands, tone-on-tone luxury |

| UV Print | Modern gloss / precise lines | High | Medium–High | No die (faster setup) | $–$$ | Fine detail, short runs, quick launches |

| Metal Badge | 3D, weighty, iconic | 3D geometry | Excellent | Custom tooling | $$$ | Flagship SKUs, collector editions |

Pro tip: if you want the shine of foil and the depth of deboss, ask for foil-deboss on a flattened patch of PU—luxury signal goes up without metal-badge cost.

How to Choose the Right Method

- Brand Positioning

- Heritage/minimalist → Deboss/Emboss

- Fashion/luxury shine → Foil or Metal Badge

- Modern/graphic → UV Print

- Logo Complexity

- Hairlines, micro text → UV Print

- Bold monograms → Foil / Deboss / Badge

- Substrate & Color

- Deep textures reduce detail; consider a flat logo patch.

- Dark matte bases amplify foil and UV gloss.

- Budget & MOQ

- Fast launch, small run → UV Print

- Mid run, classic luxury → Foil or Deboss

- Hero product → Metal Badge

- Durability Needs

- Heavy retail handling or long-term reuse → Deboss/Emboss or Badge

Case Snippets (What Works in the Wild)

- Boutique fine-jewelry line: matte cream PU with gold foil-deboss on lid center—clean, feminine, photogenic for e-com.

- Modern DTC brand: charcoal paper-wrap with spot UV logo on a wide band—sleek, contemporary, budget-friendly for drops.

- Flagship collection: pebbled black PU + brushed gold metal badge riveted on a stitched patch—statement piece worthy of display.

Engineering Notes (Save Cost & Rework)

- Logo safe zone: keep at least 10–15 mm from edges, seams, or hard curves to ensure even pressure or adhesion.

- Die sharing: if your logo size is consistent across SKUs, one die can serve multiple boxes.

- Pantone realities: metallic foils are not Pantone inks; align expectations in the sample stage.

- QC checkpoints: scuff test for foil/UV, pull test for badges, depth uniformity for deboss.

Next Steps

When you’re ready to specify finishes, send your logo (vector) and target substrate. We’ll prototype 2–3 logo methods side by side so you can see and feel the difference before locking production.

- Explore: Custom Jewelry Boxes with Logo

- Explore: High-End Jewelry Boxes

- Get Samples & Pricing: /contact-us/

FAQs

Which logo method is best for textured PU?

For heavy textures, deboss gives the cleanest result. If you want shine, use foil-deboss on a flattened patch to preserve edge clarity.

Does foil stamping fade or peel?

High-quality foil with proper temperature/pressure has strong adhesion. It won’t “peel,” but extreme abrasion can reduce gloss over time. A topcoat is not typical on PU foils.

Can UV handle very small text?

Yes—UV excels at micro-detail. Confirm minimum stroke width with your factory (often ≥0.15–0.2 mm) and run a sample.

Is a metal badge too heavy for small boxes?

Badges add weight and cost. For small keepsake boxes, a foil-deboss may deliver comparable luxury at lower cost and shorter lead time.

Can I mix methods across one collection?

Absolutely. Many brands run deboss for core SKUs and metal badges for limited editions, while keeping color/material consistent.